(updated 08/05/10)

|

(updated 08/05/10) |

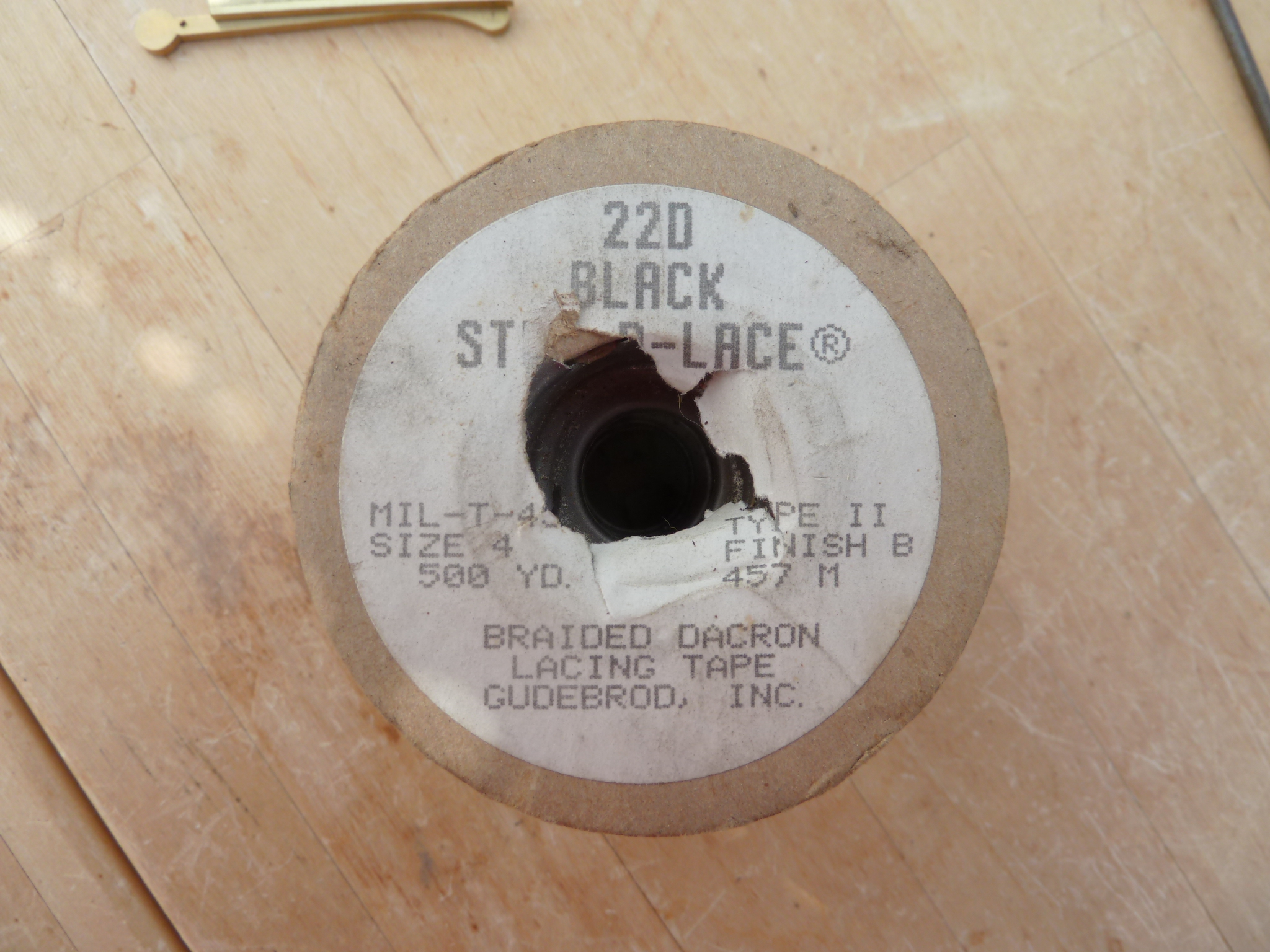

Here are some pictures of the reel I am still using. The tape measures just over 2mm wide x 0.3mm thick. It has an impregnation of some sort of wax and is almost unbreakable. when I started making I tried a lot of different threads for tying in stocks but once I tried this material I have never found better!

The reel end. |

The reel end |

The reel |

The tape |

© 1996 mike@mike-nelson.co.uk

© Mike Nelson. All rights reserved.

This manual has been put together by Mike Nelson for his own amusement :)

Go back to Mike Nelsons Home Page