Mandolin Construction Methods

Thicknessing the sides

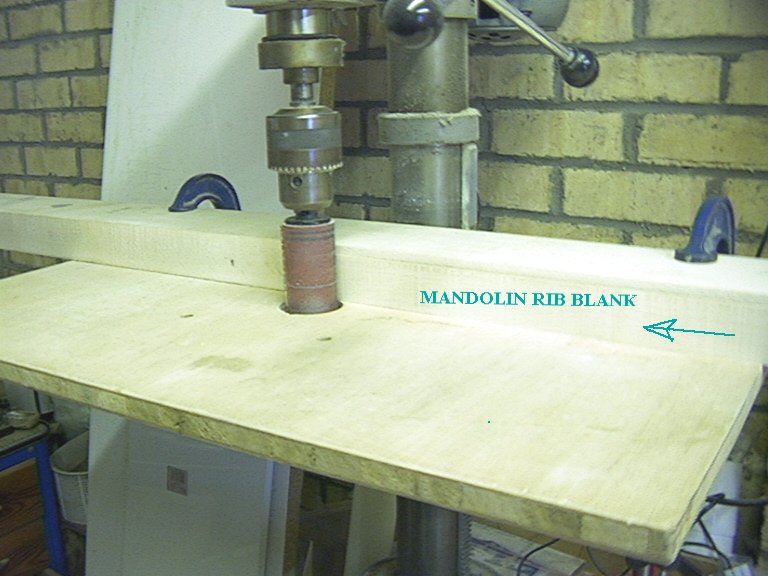

The danding drum is a commercial unit that clamps a piece of coarse(ish)sandpaper. The guide is just a piece of maple (actually it is a bit I bought to make mandolin necks from and it has a good square edge. This is clamped behind the drum and adjusted to apply the right amount of pressure to the side blank. Don't try to do all the work with one setting or you will burn the sandpaper. Set the gap to give a good firm cut and pass the wood through from right to left (as shown by the arrow)until the cutting stops.

Treat this tool with caution as it will sand flesh just as easily as wood. Not that if you let go of the wood it will fly out to the right so you might want to be sure that it wont hit anything important!

I make the sides somewhat thinner than I have read in the mandolin making books and plans. This is probably not significant from a tone point of view but it does make the manual bending process less traumatic. The thickness I use is 0.045" to 0.060" - I looked back in my notes and see that I always aimed at 0.045" for violas but I am currently using 0.060 for my last F5 copy and the A5 mandolin I am currently making.