Page 3

|

Page 3 |

|

|

|

|

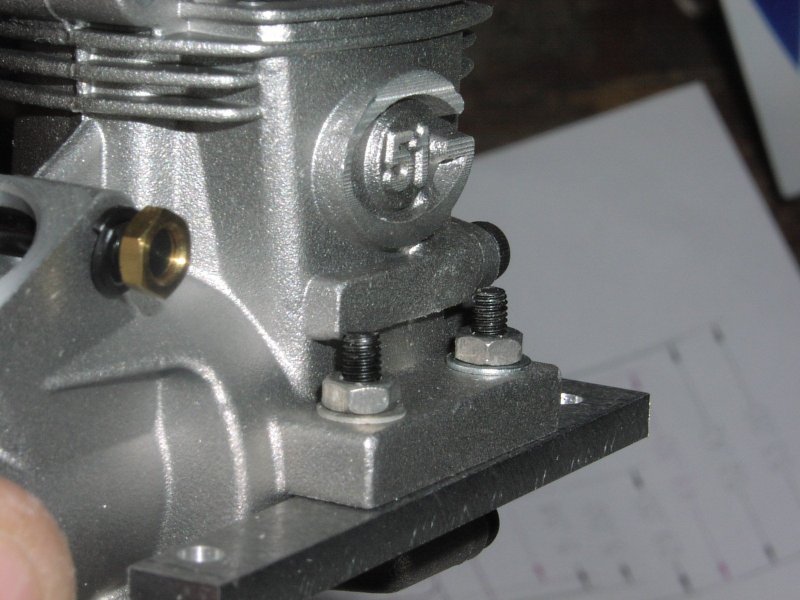

The head before machining starts. Only the chamfer has been done. the sealing face is about 0.4mm above the squish face |

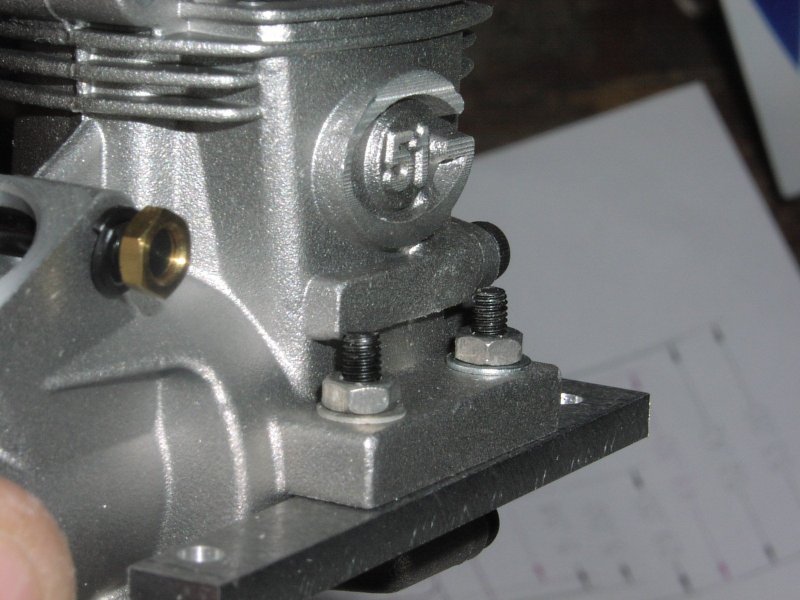

The sealing face has been machined until flush with the squish band. Only a clean-up skim has been taken from the squish band. |

|

|

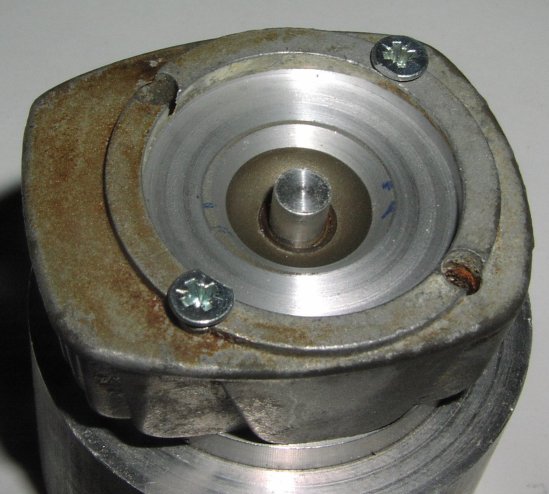

| The head is set up in the milling machine. I took a lot of care to get the face for the slot truly parallel to ensure that the slot was the same depth at both sides. | The slot has been machined exactly 1.15 deep to match with the 1.15mm thick mild steel sheet that I plan to make the shield from. |

|

|

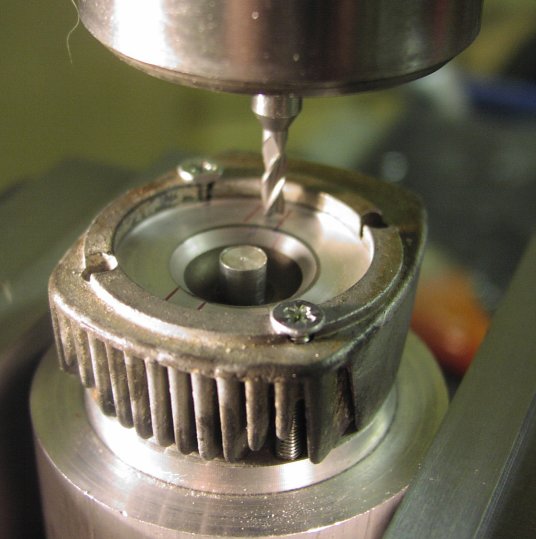

| The plug shield is made from 1.15mm mild steel and is 3mm wide by 26mm long. Ideally I would have used 1mm thick but didn't have any to hand. I don't believe that this extra few thou of thickness will make any difference. It is very important that the groove is exactly the right depth for the material used to ensure that there are no leaks. I painted a little bit of Loctite 601 into the slot before pressing the shield bar into it. | The head modifications are finished off by fitting a 0.6mm thick aluminium shim over the steel strip. I coated the mating face with a very thin skim of JB Weld to ensure that the resulting assembly was fully sealed. I chose 0.6mm as I had removed 0.4mm already and needed to put that back and on my other engines I had 0.5mm of shims in addition to the head gasket. I expect to need another couple of shims possibly up to 0.4mm to get the compression back to an ideal setting. |