|

Thoughts, experiences and repairs to the Brodak B40 |

|

Introduction

In 2005 I purchased 2 Brodak B40s. I had problems running in the first one as it was very tight at TDC and this caused the engine to display some very vicious tendences. I didn't realise at the time that the problems were due to the very tight piston fit but experience of running in the second engine which had a much more gentle pinch at TDC has convinced me that the vicious nature of the first engine was entirely due to the excessive piston fit. This was the engine that I started using when I entered stunt competitions for the first time. The first problems I had was the sudden stopping of the just run-in Brodak 40. The engine would run normally and sound happy then suddenly stop often when any extra load was applied such as the start of the wingover. I tried a lot of suggested cures for this but, as I was already using the generally accepted fuel mix for this engine and the plug/prop combination that most people were using successfully I was trying to think of what might be happening. I believe (with a bit of hindsight) that the problem was linked to the excessive pinch at TDC. I have discussed this at length with Brian Turner, a builder of world class engines, and we both think that this is indeed the problem. I suspect that the piston is being over-cooled by losing its heat into the liner possibly as a result of the oil film being squeezed out or squeezed too thin. This puts the wick out and the engine stops dead. when I was searching for a cure I pulled off the head and the top of the piston was completely clean - no sign of carbon which made me think that running temperature was implicated in the problem. My first idea for solving the problem was to shroud the head as described below. This was to increase the temperature of the top of the engine thus reducing the interferrence of the piston in the liner. This happens as the liner expands at a (slightly) greater rate than the piston and the ideal gives a perfect friction free fit at running temperature. By increasing the running temperature I believe that I reduced the pinch of the liner on the piston. I have been told that the earlier versions of the B40 had a bit too much interferrence - as much as 60 microns and this has been halved for the later ones. I would guess that my first one was at the upper end and the second one at the lower end.

Fuel 11% synth 11% castor 10% nitro and the engines were run in rigorously to the letter of the Brodak recommendations..

Curing the engine flameout.

|

|

|

Shroud fitted to the engine. The ply end piece clips into the recess between the head and the crankcase |

The shroud - note the 1/16"ply with a smaller i/d |

This modification completely cured the sudden stopping of the engine and made it very usable.

After the first 4 competitions I found that I could discard the shroud and the engine showed no signs of stopping.

These engines are very good performers and I am very happy with the performance. I won the class 2 league using this engine and had mostly good flights.

At the end of the season I was noticing and increasing amount of play in the crankshaft and significant fuel spray from the front of the engine. It was also needing about 5/6cc more to do the schedule at the end of the season compared to the start of the season. I stripped the engine down to identify the cause and embarked on a repair. I documented this on the Stuka Stunt forum but, as is the way with forums, the thread has lost the pictures so I have repeated the description here.

Curing play in the crankshaft.

|

|

|

|

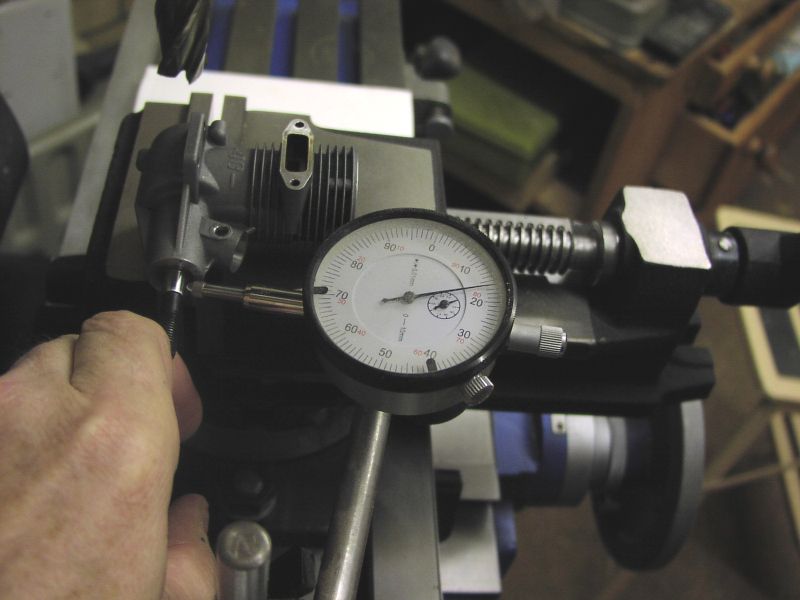

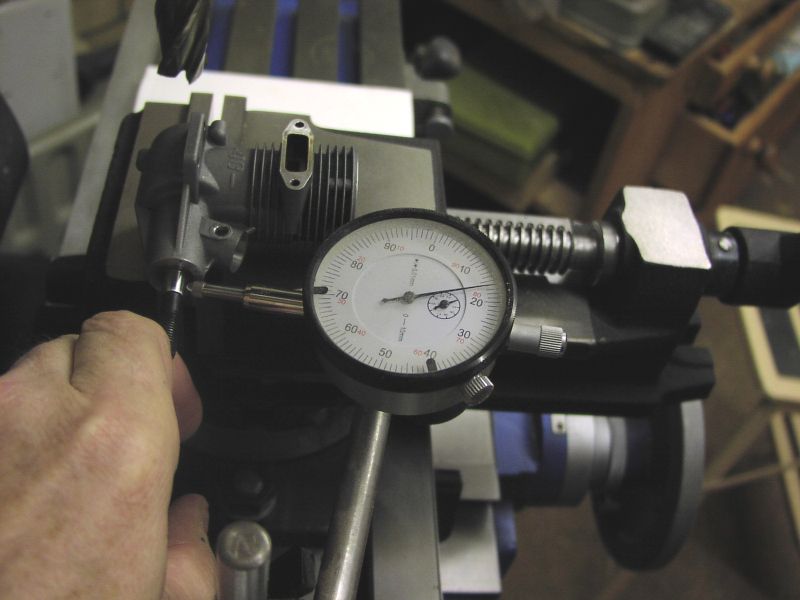

I measured the play by mounting engine and using a dial gauge |

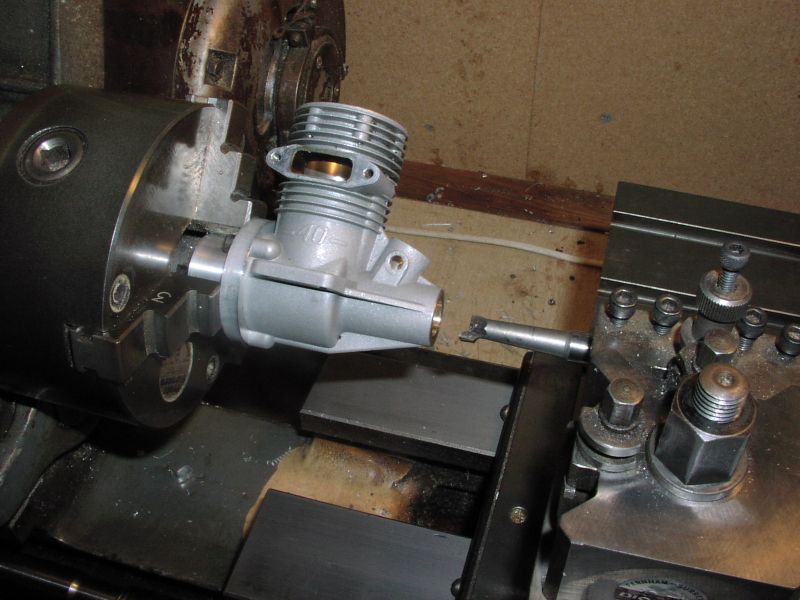

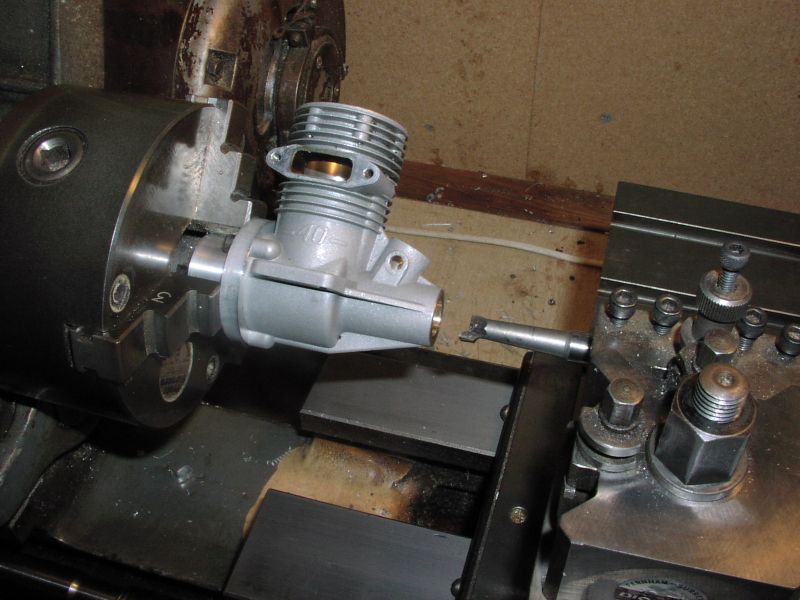

The case was mounted on a jig and held in the lathe for boring the old bushes out |

Boring the old bushes out |

Most(well at least 50%) of the 0.007" play is due to the 2 short bronze bushs being loose. They are cast in and have a knurled outside diameter to stop rotation and a groove to keep them in. It is this diameter that has come loose. I will bore out the bushes, loctite in a new single bush right through to replace the 2 short bushes of the original and bore the bush to fit the shaft. I will grind or lap the O/D of the shaft to remove the wear in the area of the inlet port that seems to be a result of a very porous area of the casting that may be harboring some foreign grit.

Actually the casting quality is not great as there are rather a lot of blow holes in the machined areas.

|

|

|

|

The case after the existing bearing have been removed showing the area of porosity. |

part way through the boring of the case the existing brgs dropped out and you can see the way they were held in when cast in place. |

here are the fragments of the bearings showing the knurled outside. |

Brodaks have been very helpful and have sent new parts. I finished the update/repair of the engine in 2006 and have been campaigning a Mo-Best with a SuperTigre 51 since then. I did try a tongue muffler on my second B40 that has had 8 flights and is better than the one that I campaigned last year. It is still tricky to get a good run right through the flight and I was hoping that a little muffler presure would help. I tapped 4 of the holes and plan to try blocking them although trials show that it will be OK as it is. This muffler is now being used by the friend who now has this engine still in the original profile Orental and it seems to perform well.

Tongue muffler for the B40.

I don't understand why we see so few tongue mufflers in the UK. They seem to work well, are very light (mine is less than 1/2 oz) and really easy to make. They seem quite common in the US.

|

|

| Muffler | click to see full drawing |

© 2013 Mike Nelson. All rights reserved.

Go back to Mike Nelsons controline Home Page

Go back to Mike Nelsons Home Page

This site is created and maintained by Mike Nelson for his own pleasure